VDQ-NRG Waste Reprocessing Solution

VDQ-NRG Systems has brought together multiple innovative technologies to form a streamlined and effective total waste-stream solution. Integrating processes creates value from products that would otherwise be discarded in a landfill. We are turning waste into energy using thermo-chemical processes, with no need to reduce the moisture content of the waste. Our solution does not burn the waste, it is not incineration, gasification or pyrolysis. The self contained and compact design of the facility allows it to be located in areas where traditional waste gathering plants and landfills would not be practical or welcomed.

Household waste is picked up at the door using a single stream program. Existing city trucks or city approved contractors will collect the waste and transport it to the processing facility. Waste collection is streamlined and the trucks will have less distance to travel.

An artificial intelligence, automatic customer management system tracks weights coming in while minimizing interaction with facility personnel. The system provides a complete audit trail to ensure compliance with environmental regulations, and enables a short turn around time for trucks unloading.

Standard sorting technology will be sourced from companies such as Vecoplan or Machinex. These companies have extensive experience in sorting wastes and recycling around the world.

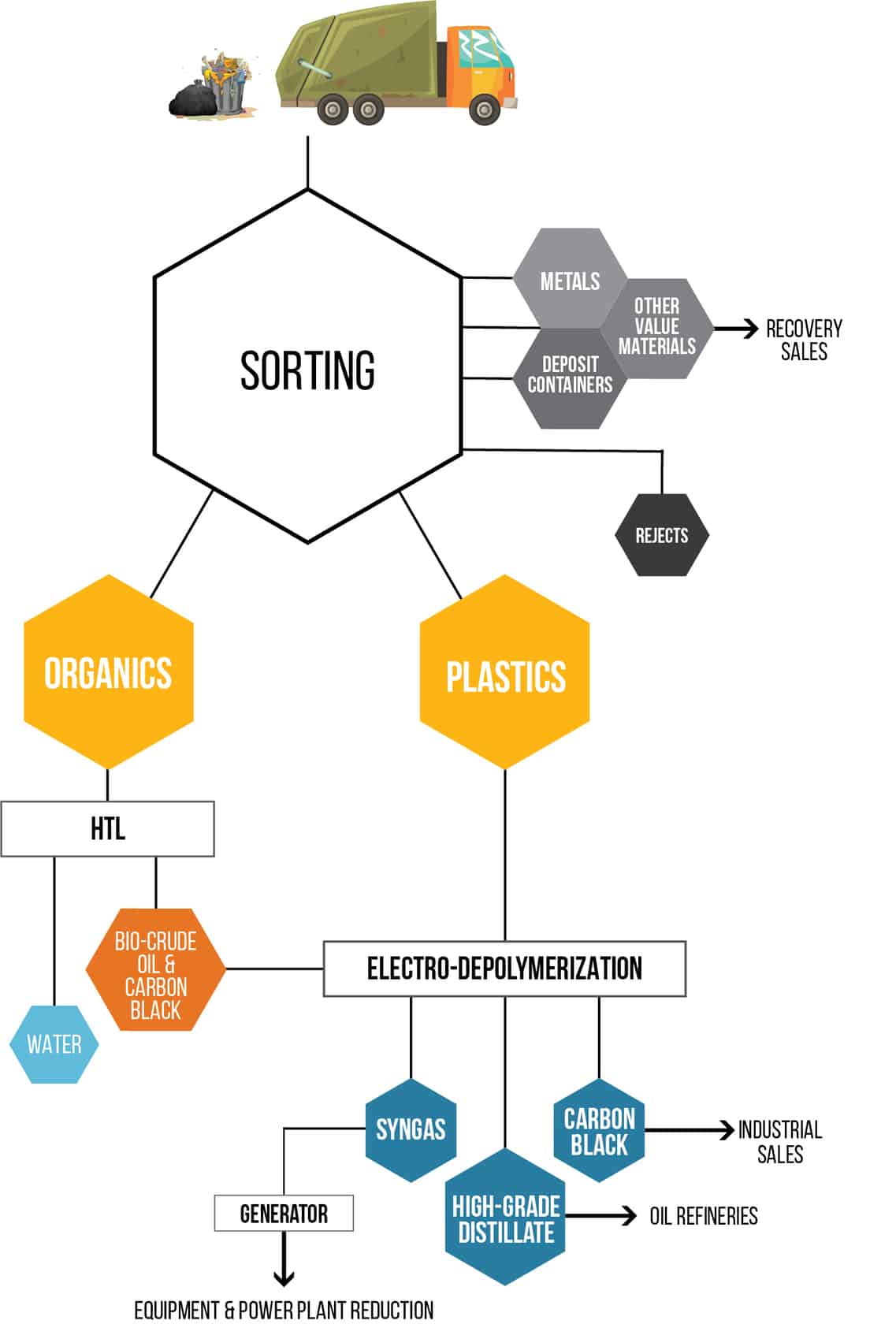

Plastics and organics are separated from high value materials and non-processable materials. Metals, deposit containers, and other materials of value will be sold. Reject materials such as stones, glass and brick will be removed from the system and sent to the landfill for recovery or disposal.

Plastics are processed using Electro-Depolymerization, a system that converts waste plastics into pyro crude oil. The syngas by-product is used to run a high efficiency generator to provide power to the facility. The carbon black by-product is removed from the chamber and sold. A second Electro-Depolymerization tank gasifies the pyro crude oil, which is passed over a non-consumable catalyst. The gases cool and liquify, then settle into a series of distillation tanks, separating out the different fractionation of fuel products, primarily high-grade distillate fuel.

Organics are processed using Hydrothermal Liquefaction (HTL), a continuous thermal-chemical process that breaks down and liquifies organic materials. The reaction occurs under high pressure and temperature, using water as a catalyst to reform the organic materials into long chain hydrocarbons of bio-crude oil, and by-products including carbon black. Once the water is removed, the bio-crude and carbon black are processed through the Electro-Depolymerization system to upgrade the fuel into high grade distillate. Due to the challenges of refining bio-crude oil, upgrading on-site into high grade distillate allows for more effective monetization of the product.

VDQ-NRG is committed to continuous improvement. We will strive to improve our current technologies as well as adding further technologies to enhance the ability to generate value from the waste products delivered.